| Engine Model | Cat® C18 ACERT™ |

| Flywheel Power | 306 kW410 HP |

| Bore | 145 mm5.7 in |

| Stroke | 183 mm7.2 in |

| Displacement | 18.1 l1106 in³ |

| Emissions | U.S. EPA Tier 2/EU Stage II Equivalent and U.S. EPA Tier 3/EU Stage IIIA Equivalent |

| Engine Power - Gross SAE J1995* | 334 kW448 HP |

| Engine Power - ISO 14396 | 329 kW441 HP |

| Engine Power - Net SAE J1349/ISO 9249 | 306 kW410 HP |

| Net SAE J1349/ISO 9249 | 306 kW410 HP |

| Note (1) | * Excludes all fan losses. |

| Operating Weight | 47872 kg105539 lb |

| Shipping Weight | 35746 kg78806 lb |

| 1 Forward | 3.9 km/h2.4 mile/h |

| 2 Forward | 6.8 km/h4.2 mile/h |

| 3 Forward | 11.7 km/h7.3 mile/h |

| 1 Reverse | 4.7 km/h2.9 mile/h |

| 2 Reverse | 8.4 km/h5.2 mile/h |

| 3 Reverse | 14.3 km/h8.9 mile/h |

| 1 Forward - Drawbar Pull | 716500 N161000 |

| 2 Forward - Drawbar Pull | 400500 N90000 |

| 3 Forward - Drawbar Pull | 222500 N50000 |

| Pump Type | Piston-type pump geared from flywheel |

| Pump Output - Steering | 387 l/min102 gal/min |

| Pump Output - Implement | 226 l/min60 gal/min |

| Tilt Cylinder Flow - Rod End Flow | 140 l/min37 gal/min |

| Tilt Cylinder Flow - Head End Flow | 188 l/min50 gal/min |

| Bulldozer Relief Valve Setting | 26200 kPa3800 psi |

| Tilt Cylinder Relief Valve Setting | 19300 kPa2800 psi |

| Ripper - Lift - Relief Valve Setting | 26200 kPa3800 psi |

| Ripper - Pitch - Relief Valve Setting | 26200 kPa3800 psi |

| Steering | 40500 kPa5875 psi |

| Tank Capacity | 89 l23.5 gal (US) |

| Shoe Type | Extreme Service |

| Width - Shoe | 610 mm24 in |

| Shoes/Side | 43 |

| Grouser Height | 84 mm3.3 in |

| Pitch | 240 mm9.44 in |

| Ground Clearance | 596 mm23.5 in |

| Track Gauge | 2250 mm88.6 in |

| Length - Track on Ground | 3470 mm136.6 in |

| Ground Contact Area | 4.24 m²6569 in² |

| Track Rollers/Side | 8 |

| Number of Carrier Rollers | 1 per side (optional) |

| Fuel Tank | 889 l235 gal (US) |

| Cooling System | 101 l26.7 gal (US) |

| Engine Crankcase* | 34 l9 gal (US) |

| Power Train | 164 l43.3 gal (US) |

| Final Drive - Each | 15 l3.9 gal (US) |

| Roller Frames - Each | 45 l11.9 gal (US) |

| Pivot Shaft Compartment | 30 l7.9 gal (US) |

| Hydraulic Tank Oil - Only | 89 l23.5 gal (US) |

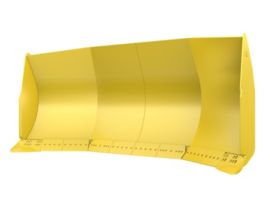

| Capacity - SAE J1265 | 13.5 m³17.7 yd³ |

| Digging Depth | 606 mm23.9 in |

| Ground Clearance | 1422 mm56 in |

| Height | 1934 mm6.35 ft |

| Maximum Tilt | 940 mm37 in |

| Total Operating Weight** - With Blade and Single-Shank Ripper | 47872 kg105539 lb |

| Weight* - Without Hydraulic Controls | 6863 kg15130 lb |

| Width - Over End Bits | 4310 mm14.14 ft |

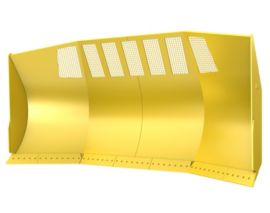

| Capacity - SAE J1265 | 16.4 m³21.4 yd³ |

| Digging Depth | 606 mm23.9 in |

| Ground Clearance | 1422 mm56 in |

| Height | 1934 mm6.35 ft |

| Maximum Tilt | 1014 mm39.9 in |

| Total Operating Weight** - With Blade and Single-Shank Ripper | 48460 kg106836 lb |

| Weight* - Without Hydraulic Controls | 7388 kg16288 lb |

| Width - Over End Bits | 4650 mm15.25 ft |

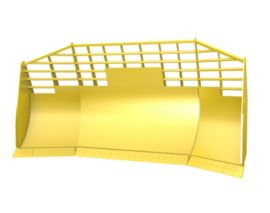

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | 882 mm/817 mm (34.7 in/32.2 in) |

| Maximum Penetration - Standard Tip | 1231 mm/1727 mm (48.5 in/68 in) |

| Maximum Penetration Force - Shank Vertical | 158 kN/172 kN (35,520 lbf/38,667 lbf) |

| Note (1) | * Total Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU-Blade, Ripper, 610 mm (24 in) ES shoes, and operator. |

| Note (2) | Single-shank ripping arrangement weight includes pin puller. |

| Number of Shank Holes | 3 |

| Overall Beam Width | NA |

| Pry-Out Force | 332 kN/331 kN (74,637 lbf/74,412 lbf) |

| Total Operating Weight* - With SU-Blade and Ripper | 47872 kg105539 lb |

| Weight - With One Shank | 4293 kg/4420 kg (9,464 lb/9,744 lb) |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | 879 mm34.6 in |

| Maximum Penetration - Standard Tip | 798 mm31.4 in |

| Maximum Penetration Force - Shank Vertical | 154 kN34621 lb |

| Note (1) | * Total Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU-Blade, Ripper, 610 mm (24 in) ES shoes, and operator. |

| Note (2) | + Includes (1) shank, add 347 kg for each additional shank. |

| Number of Shank Holes | 2 |

| Overall Beam Width | 1330 mm4.36 ft |

| Pry-Out Force - Multi-Shank Ripper with One Tooth | 361 kN81156 lb |

| Total Operating Weight* - With SU-Blade and Ripper | 48221 kg106309 lb |

| Weight - With One Shank | 4153 kg9156 lb |

| Winch Model | PA140VS |

| Weight* | 1790 kg3950 lb |

| Oil Capacity | 15 l4 gal (US) |

| Increased Tractor Length | 557 mm21.9 in |

| Drum Width | 320 mm12.6 in |

| Wire Cable Diameter - Optional | 32 mm1.25 in |

| Wire Cable Diameter - Recommended | 28 mm1.13 in |

| FOPS | FOPS (Falling Object Protective Structure) meets ISO 3449:2005 Level II. |

| ROPS | ROPS (Rollover Protective Structure) offered by Caterpillar for the machine meets ROPS criteria SAE J1040 MAY94, ISO 3471:1994. |

| Note (1) | * Includes blade installation arrangement, blade tilt cylinder, and blade lift cylinders. |

| Note (2) | ** Total Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes, and operator. |

| Note (1) | * Includes blade installation arrangement, blade tilt cylinder, and blade lift cylinders. |

| Note (2) | ** Total Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes, and operator. |

| Drawbar Height (Center of Clevis)* | 763 mm30 in |

| Ground Clearance* | 596 mm23.4 in |

| Height - FOPS Cab* | 3820 mm150.4 in |

| Height - ROPS/Canopy* | 4000 mm157.5 in |

| Height - Top of Stack* | 3919 mm154.3 in |

| Length - Basic Tractor - With Drawbar | 5180 mm204 in |

| Length - Basic Tractor - With Winch | 5545 mm218.3 in |

| Length - Track on Ground | 3470 mm136.6 in |

| Length - With Multi-Shank Ripper | 6538 mm257.4 in |

| Length - With SU-Blade** | 6880 mm270.9 in |

| Length - With Single-Shank Ripper | 6529 mm257 in |

| Length - With U-Blade | 6967 mm274.3 in |

| Note (1) | *Includes grouser height for total dimensions on hard surfaces. |

| Note (2) | **Includes drawbar. |

| Overall Length - Basic Tractor | 4910 mm193.3 in |

| Overall Length - SU-Blade/SS Ripper | 8230 mm324 in |

| Track Gauge | 2250 mm88.6 in |

| Width - Over Trunnions | 3300 mm129.9 in |

| Width - Without Trunnions - Standard Shoe | 2880 mm113.4 in |

| Note (2) | Engine ratings apply at 1,833 rpm. |

| Note (3) | Net power advertised is the power available at the flywheel when the engine is equipped with fan at max speed, air cleaner, muffler and alternator. |

| Note (4) | No derating required up to 2286 m (7,500 ft) altitude. High altitude attachment available for greater than 2286 m (7,500 ft). |

| Note (1) | Steering Pump output measured at 1,800 rpm and 30 000 kPa (4,351 psi). |

| Note (2) | Implement Pump output measured at 1,800 rpm and 20 000 kPa (2,900 psi). |

| Note (3) | Electro-hydraulic pilot valve assists operations of ripper and dozer controls. Standard hydraulic systems includes four valves. |

| Note (4) | Complete system consists of pump, tank with filter, oil cooler, valves, lines, linkage and control levers. |

| Note | * With oil filters. |

| Sound (1) | Operator sound exposure Leq (equivalent sound pressure level) measured according to the work cycle procedures specified in ANSI/SAE J1166 OCT98 is 77 dB(A), for cab offered by Caterpillar, when properly installed and maintained and tested with the doors and windows closed. |

| Sound (2) | The exterior sound pressure level for the standard machine measured at a distance of 15 m (49 ft) according to the test procedures specified in SAE J88 APR95, mid-gear-moving operation, is 87 dB(A). |

| Note | Positive Pin Retention Track. |

| Note (1) | Operating Weight: Includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU-Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes, and operator. |

| Note (2) | Shipping Weight: Base machine chassis with cab, pivot shaft, roller frames, track and ROPS. |

| Maximum Drum Capacity - Optional Cable Length | 62 m204 ft |

| Maximum Drum Capacity - Recommended Cable Length | 78 m257 ft |

| Note (1) | Variable speed, hydraulically driven, dual braking system, three-roller fairlead. |

| Note (2) | * Weight shown is base winch only. Does not include mounting arrangement, control arrangement, oil, or wire rope. With counterweight: 3700 kg (8,150 lb). |

| Wire Cable Ferrule Size - Length | 70 mm2.8 in |

| Wire Cable Ferrule Size - Outside Diameter | 60 mm2.4 in |