Powerful Performance -

The Cat C9 electronically controlled ACERT engine delivers power while meeting all current U.S. EPA emission standards. All models contain a fuel/water separator, engine air intake heater and a dual-stage combination air cleaner with precleaner.

High Capacity Cooling System -

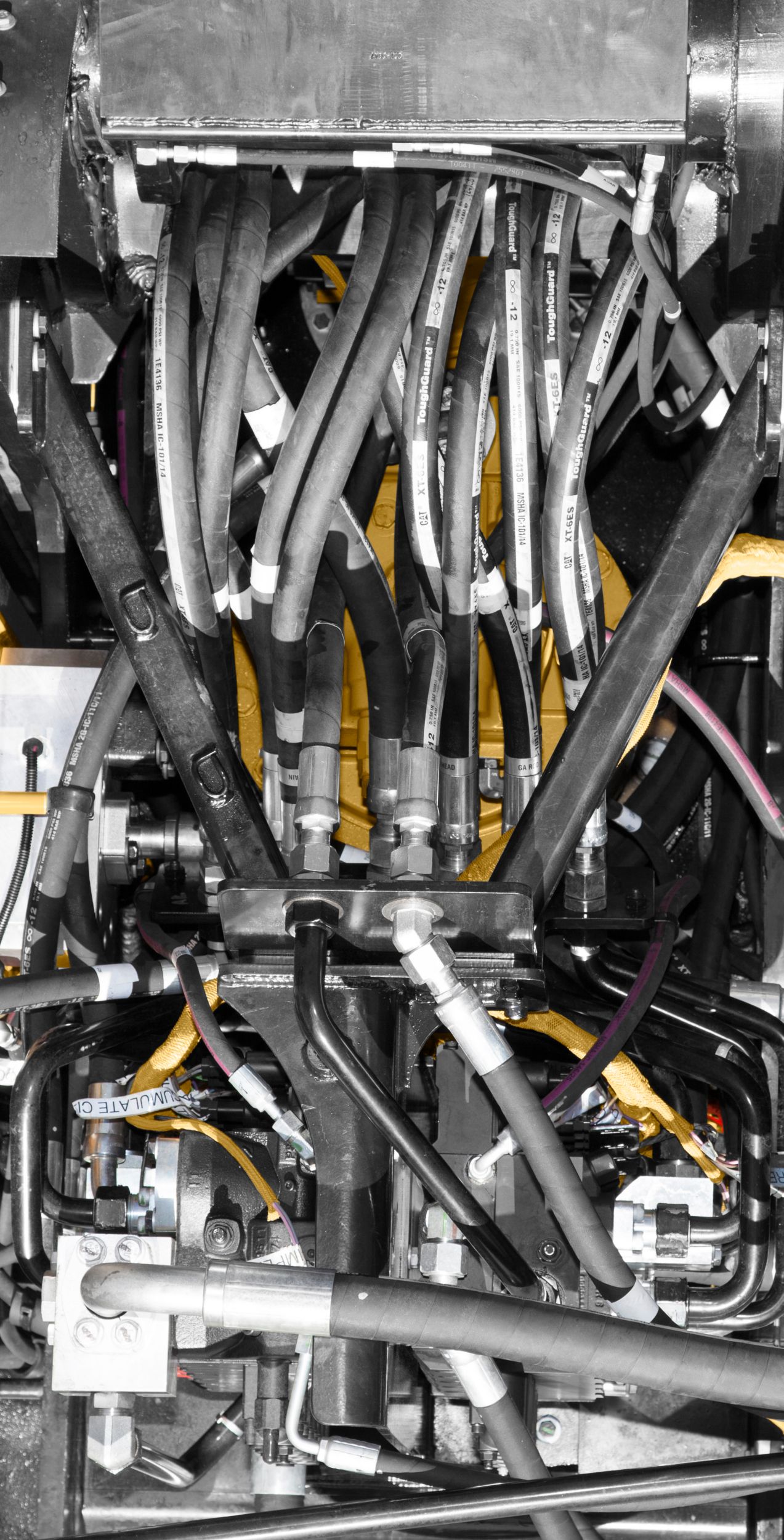

The side-by-side radiator/oil cooler gives excellent cooling capacity for high production bunching and harvesting. On-demand Flexxaire fan activates only when required and allows the cooling fan to purge debris from the radiator area, keeping a cleaner cooling system. The IQAN control system automatically adjusts the Flexxaire fan blade angle, reducing horsepower demand and lowering fuel consumption. The purge cycle frequency and duration can be set by operator in the cab to suit varying application conditions.

Engine Oil -

Cat engine oil is formulated to optimize engine life and performance and is recommended for use in Cat diesel engines. Extended oil change intervals reduce maintenance and machine downtime.

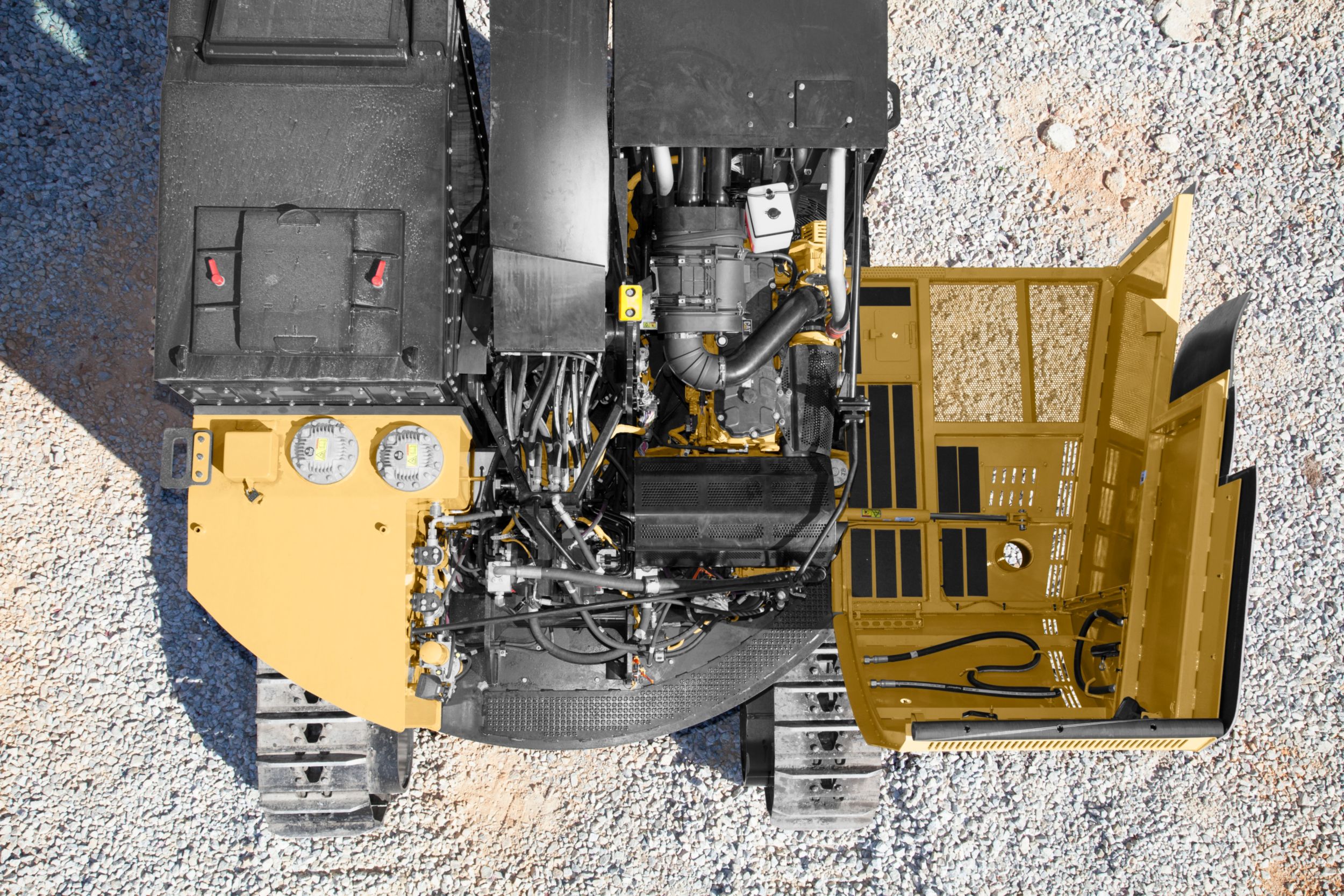

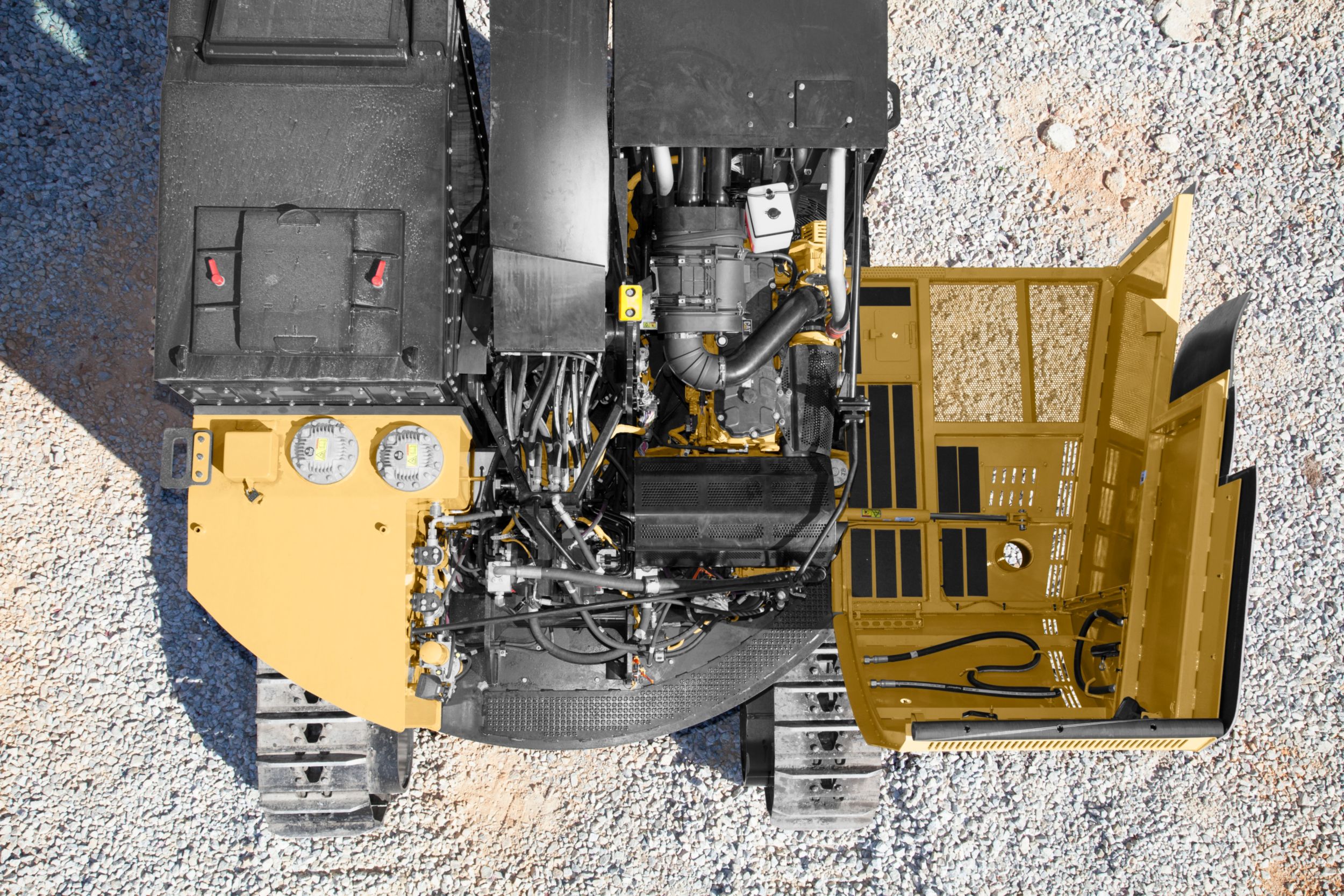

Service -

The clamshell style engine compartment provides easy access to all filters, oil dipstick, coolant reservoir, hydraulic fill pump, valves and hoses reducing maintenance time.

Low Exhaust Emissions -

The Cat C9 ACERT engine is a low emission engine designed to meet U.S. EPA emission regulations.

Batteries -

An optional starting aid for colder climates is available for 522B machine models. This option provides two (2) additional batteries and HD battery cables.