| Typical Machine Length | 14 m46.16 ft |

| Installed Power | 1200 kW1897 HP |

| Haulage System | 2 × 85 kW (2 × 115 hp) |

| Seam Range | 1.6-3.2 m (63-126 in) |

| Installed Power | Up to 1200 kW (Up to 1,609 hp) |

| Typical Machine Length - Drum Centers | 14065 mm46.16 ft |

| Available Cutting Power | 2 × 500 kW (2 × 671 hp) |

| Cutting Drum Diameter | 1400 to 2000 mm (55 to 78 in) |

| Cutting Drum Speed | 33.5, 38.8 and 43.8 rpm |

| Haulage System | 2 × 85 kW (2 × 115 hp) |

| Haulage Speed | Up to 29.5 m/min (Up to 97 ft/min) |

| Haulage Pull | Up to 690 kN/77.9 tons |

| Pump Motor | 30 kW40.2 HP |

| Body Height | 550 mm21.6 in |

| Machine Weight - Approximate | 60 ton (US)66 ton (US) |

| Operating Voltage | 3300 V3300 V |

| Minimum Pan Width | 832 mm32.7 in |

| Seam Range | 1.6-3.2 m (63-126 in) |

| Installed Power | Up to 1414 kW (Up to 1,897 hp) |

| Typical Machine Length - Drum Centers | 14065 mm46.16 ft |

| Available Cutting Power | 2 × 597 kW (2 × 800 hp) |

| Cutting Drum Diameter | 1400 to 2000 mm (55 to 78 in) |

| Cutting Drum Speed | 40.2, 46.6 and 52.5 rpm |

| Haulage Control | AC inverter drive |

| Haulage Control | AC inverter drive |

| Haulage System | 2 × 85 kW (2 × 115 hp) |

| Haulage Speed | Up to 29.5 m/min (Up to 97 ft/min) |

| Haulage Pull | Up to 690 kN/77.9 tons |

| Pump Motor | 36 kW48 HP |

| Body Height | 550 mm21.6 in |

| Machine Weight - Approximate | 60 ton (US)66 ton (US) |

| Operating Voltage | 4160 V4160 V |

| Minimum Pan Width | 832 mm32.7 in |

| RA560 (1) | Designed and robustly tested – for longer service life. |

| RA560 (10) | Available cutter motors – 500 kW @ 50 Hz (810 hp @ 60 Hz) |

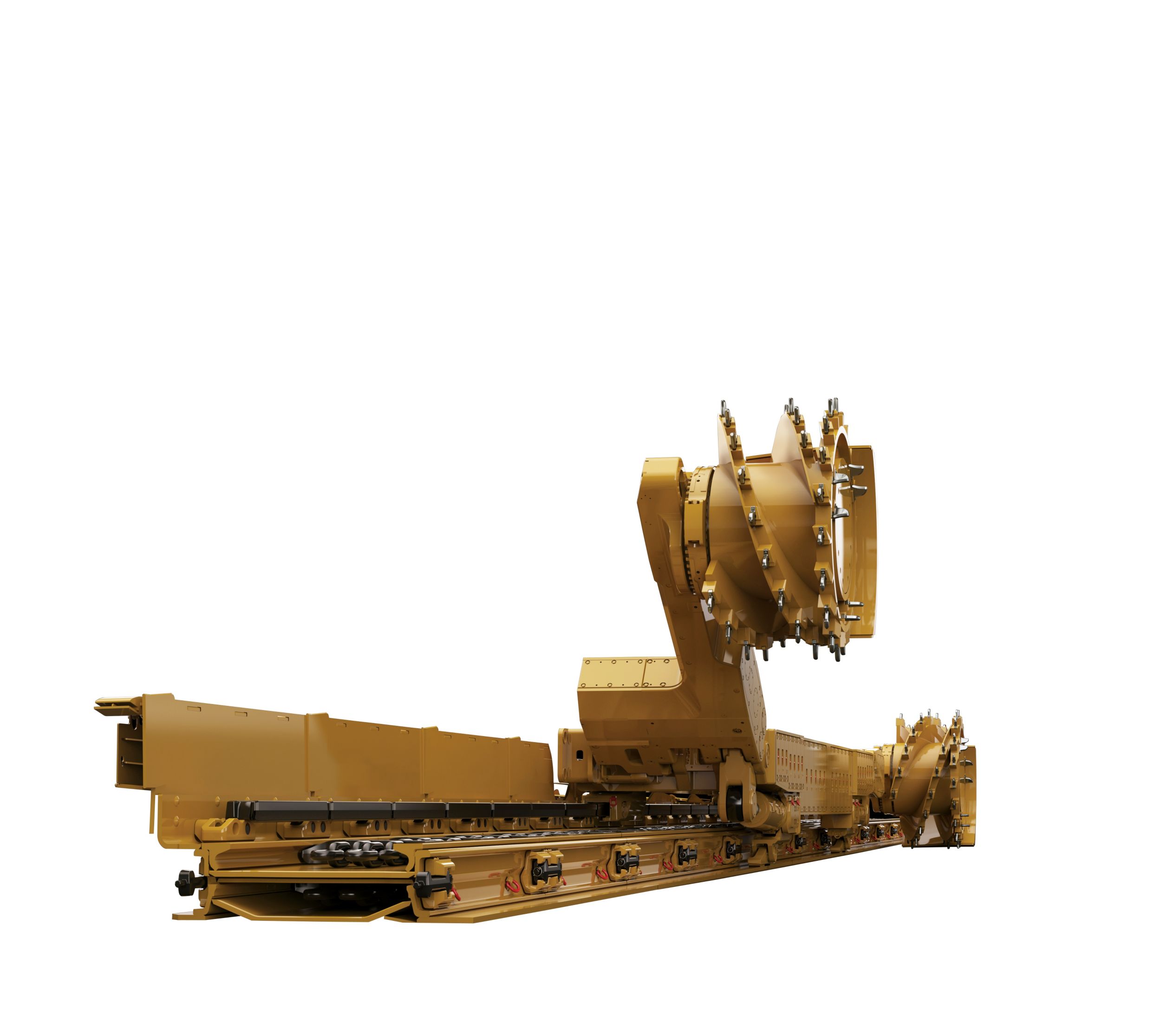

| RA560 (2) | Transmission rating of 500 kW @ 33.5 rpm and above (40 rpm @ 60 Hz) |

| RA560 (3) | Maximum drum diameter of 2000 mm (78 in) |

| RA560 (4) | Choice of drum speeds |

| RA560 (5) | Complete with 32 mm (1.3 in) bore, through shaft PFF/PBF wet cutting |

| RA560 (6) | Square drum hub (440 mm [17.3 in] across flats) |

| RA560 (7) | Integral monitoring transducers |

| RA560 (8) | Quillshaft transmission protection |

| RA560 (9) | A robust cowl drive mechanism is also available on this model |

| Maximum Machine Speed | 29.5 m/min96.77 ft/min |

| Pull at Maximum Speed | 345.7 kN (38.9 tons) |

| Speed at Maximum Pull | 14.75 m/min48.39 ft/min |

| Total Machine Pull | 690 kN (77.9 tons) |

| Type (1) | Maximum power rating 85 kW (115 hp) |

| Type (2) | Transmission reduction of 132.6:1 |

| Type (3) | Available with Machine Position Encoder |

| Type (4) | Available with Machine Parking Brake |

| Type (5) | Integral monitoring transducers |

| Type (6) | Quillshaft transmission protection |

| Type (7) | Online vibration monitoring |

| Type (1) | Innovative and unique downdrive design |

| Type (2) | Transmission rating of 85 kW (115 hp) |

| Type (3) | Maximum haulage pull of 690 kN (77.9 tons) |

| Type (4) | Fully removable, modular gearbox |

| Type (5) | Removable modular top drive wheel assembly |

| Type (6) | Downdrive ratio 17T—23T—10T (two wheel configuration) |

| Type (7) | Trapping shoe with replaceable wear inserts, safe and easy to replace (unique to Caterpillar) |

| Type (8) | Suitable for all current rack type systems |

| Type (1) | Fixed displacement pump, with a capacity of 50 L/min (13 gal/min) |

| Type (2) | Operating system pressure of 280 bar (4,000 psi) |

| Type (3) | Robust hydraulic reservoir of 140 L (37 gal) capacity |

| Type (4) | Integral monitoring transducers |

| Type (5) | For use with ISO 68 or ISO 100 hydraulic oils |

| Type (6) | Available with 6 section valve bank |

| Type (7) | This unit has a pump motor rating of 30 kW @ 50 Hz (48 hp @ 60 Hz) |

| Type (1) | High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units |

| Type (2) | Maximum protection of electrical boxes, providing the highest level of flameproof integrity |

| Type (3) | Improved access for maintenance and ease of overhaul and repair |

| Type (4) | Versatility of application due to fully modular construction |

| Type (5) | A split mainframe is available in case of transportation limitations |

| Type (1) | This flameproof module contains the majority of the shearer electrical control and power distribution components. |

| Type (2) | High current carrying capacity of 400 amps and can accommodate trailing cables up to 185 mm2 (2.9 in2). |

| Type (3) | All internal chassis can be ‘bench built,’ tested and stored. |

| Type (4) | Box contains various LV circuit breakers which can be reset through the FLP cover, reducing downtime. |

| Type (5) | An extremely powerful PMC Evo-S control system with state-of-the-art Ethernet communication and backup functionality, this allows the shearer to be operated even if the overall control system is not functioning. |

| Type (6) | This unit also contains cutter motor contactors, circuit breakers, control transformer, current monitoring, HV fuses, earth leakage and a visible disconnect. |

| Type | This flameproof module contains the main 253 kVA haulage transformer, power supplies, auxiliary transformer, drive system circuit breaker and one 250 kW (335 hp), 600V AC inverter drive, with integrated regenerative braking. |

| Type (1) | This model of shearer is available with headlights, cameras, methane monitoring, end displays and audible alarms. |

| Type (2) | All electrical material is designed and certified to IEC standards and also complies with other regional and national standards, such as MSHA, GOST, MA, ATEX and DGMS, as well as Australia’s New South Wales and Queensland regulations. |

| Type (1) | All hose assemblies are to ISO 6805 and proof tested to EN ISO 1402. |

| Type (2) | The hoses are assembled to Hose Assembly Standard DIN20066:201-10. |

| Type (3) | All hose and hosing is in compliance with guideline MDG 41 and MSHA regulations. |

| Type (1) | All hose assemblies are to ISO 6805 and proof tested to EN ISO 1402. |

| Type (2) | The hoses are assembled to Hose Assembly Standard DIN20066:201-10. |

| Type (3) | All hose and hosing is in compliance with guideline MDG 41 and MSHA regulations. |

| Type (4) | This model of shearer is available with onboard filtration, dust suppression spray bars, shearer clearers and ranging arm spray rings. |

| Type | A comprehensive health monitoring system is available, including oil levels and temperatures, flows, pressures and vibration analysis. |

| Level of Automation (1) | Zone-based automation “Navigator 1” |

| Level of Automation (2) | State-based shearer automation “Navigator 2” |

| Level of Automation (3) | Integrated longwall automation with “Navigator 2 + 3” |

| Level of Automation (4) | “Longwall Navigator” for improved face alignment and horizon control |

| Type (1) | Industry-leading Automation from the Pioneer of State-based Automation. |

| Type (2) | This shearer has a state-of-the-art distributed automation system for the control, monitoring and protection of the shearer. Its modular design allows it to be configured to meet individual control needs, from basic monitoring and protection to advanced automation and data transmission. |

| Type (3) | The PMC-S control system with state-of-the-art Ethernet communication and backup functionality allows the shearer to be operated even if the overall control system is not functioning. |

| Type (4) | The shearer is equipped with a state-of-the-art industry PC in a flame-proof housing with plenty of computing power, allowing flexibility to upgrade to future features such as condition monitoring. |

| Type (5) | A Programmable Logic Controller (PLC) takes care of basic machine control tasks, ensuring that coal is produced. |

| Type (6) | Unlike competitor systems, the modularity of the longwall system and control allow the longwall to operate in “fault-tolerant” mode, even when there is a problem with the overall automation system. |

| Type (7) | In other words, integrated automation does not prevent control via individual PLC’s in order to keep production up and running. |

| AFC Pan Width (Typical - As Shown) | 1142 mm45 in |

| Clearance from Drum to AFC Toeplate | 271 mm11 in |

| Cutting Drum Overall Width | 1142 mm45 in |

| Diameter - Shearer Cutting Drum | 1524 mm60 in |

| Distance Between Drums with Arms Horizontal | 14065 mm554 in |

| Distance Between Ranging Arm Hinge Points | 8435 mm332 in |

| Distance Between Trapping Shoe Centers - Typical | 6381 mm251 in |

| Height - Top of Machine Main Body - Lowest Version | 1200 mm47.2 in |

| Machine Height - Over Main Body (< in lowest version) | 1200 mm47.2 in |

| Maximum Cutting Height for Seam (Plus) | 3200 mm126 in |

| Ranging Arm Cutting Drum Diameter | 1524 mm60 in |

| Ranging Arm Length - Hinge to Drum | 2815 mm110.8 in |

| Shearer Drum Undercut of Floor (>) | 500 mm20 in |

| Vertical Tunnel Clearance - Approximate | 460 mm18 in |

| Width - Across Picks | 1067 mm42 in |